About us

Henan Doing Environmental Protection Technology Co., Ltd, the subsidiary company of Doing Holdings Co., LTD, is a comprehensive environmental equipment manufacturer integrating technological design, research and development, machine production, sales and after-sales service in one.

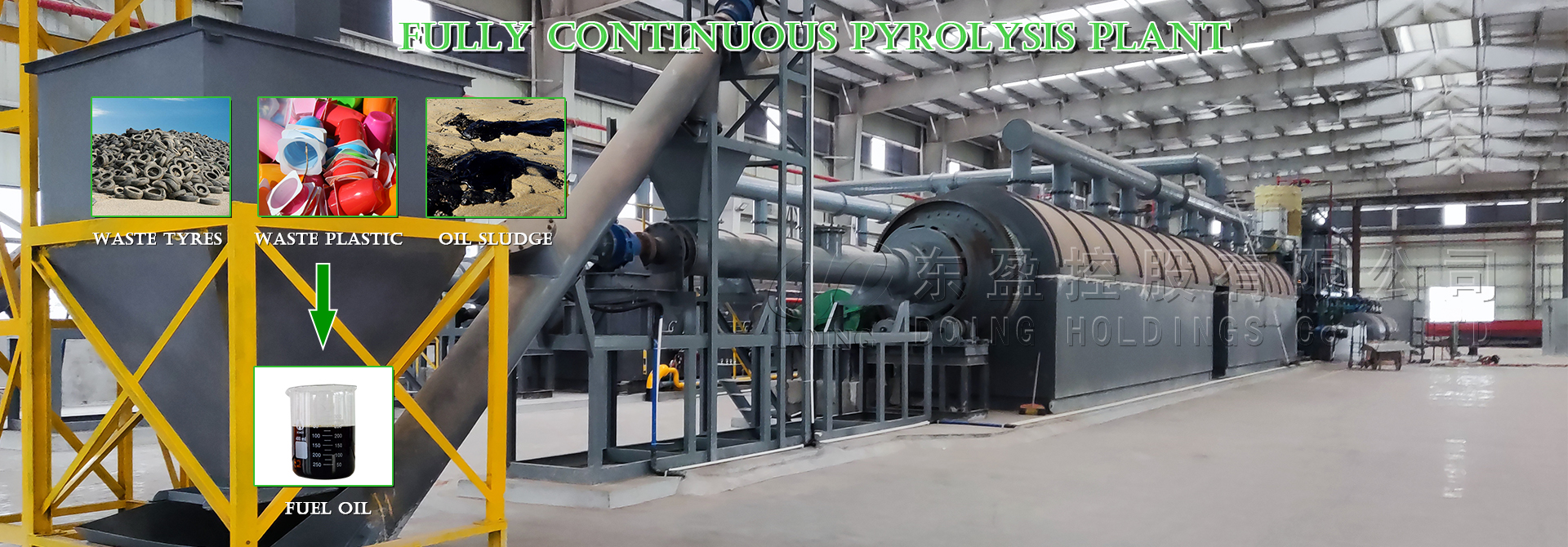

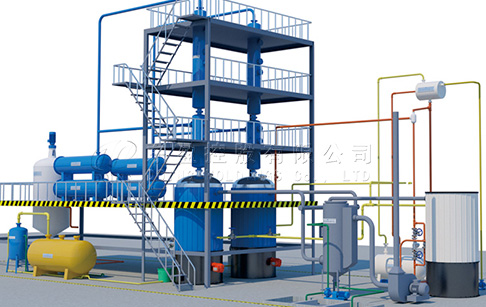

Our main business: solid waste and hazardous waste treatment equipments, pyrolysis plant and related environmental protection equipments including continuous waste tire pyrolysis plant, continuous waste plastic pyrolysis plant, continuous waste oil sludge pyrolysis plant, waste oil recycling to diesel plant, etc.

We not only possess an independent technology R&D team who have obtained a number of utility model patents and invention patents, but also have the professional manufacturing team and after-sales team to guarantee you the product quality and user experience.

Now, our products have sold well in more than 60 countries and regions around the world, winning great praise and trust of our customers all over the world! View More

-

Project description

Provide detailed project description and equipment configuration scheme.

-

Installation

Provide installation, commissioning and training service, has a professional team for after-sale service.

-

Warranty

All the products from DOING company has 12 months warranty since clients sign the act of acceptance.

-

Technical Support

Life time technical support, provide installation and debugging video and related materials.

-

On-line Service

24 hours on-line service.

Continuous waste tyre pyrolysis plant is for processing waste tyres into fuel oil and carbon black for recycle use.

- Raw Material: waste tires, waste plastics, oil sludge, coal tar

- Model: DY-C-20 DY-C-30 DY-C-50

- Operation System: Fully automatic PLC control system

DOING News

-

01-24

2025

China 50-Ton Continuous Pyrolysis Machine Order for Waste Tire Recycling

In January 2025, Doing Group got an order of 50-Ton Continuous Pyrolysis Machine from Chinese customer. The big scale py...

-

11-26

2024

Shipment of waste tire doubling and tripling machine to Bolivia

On October 30, 2024, DOING shipped a high-efficiency waste tire doubling and tripling machine which can pack two or thre...

-

09-25

2024

Semi-continuous waste tire pyrolysis machine delivered to Indonesia

On September 20, 2024, a set of semi-continuous waste tire pyrolysis machine was delivered to Indonesia, which can recyc...

-

10-20

2024

Shipping three sets of 15TPD semi-continuous tire pyrolysis units to Brazil

On Oct 10, 2024, three sets of 15TPD waste tire pyrolysis units were shipped to Brazil, which adopts the semi-continuous...

-

10-01

2024

50TPD continuous tyre oil pyrolysis plant delivered to India!

On September 26, 2024, a set of 50TPD continuous tyre oil pyrolysis plant was delivered to India after seriously packagi...

-

10-10

2024

A German customer ordered a set of continuous plastic pyrolysis machine from DOING!

In September, 2024, a German customer ordered a set of continuous plastic pyrolysis machine from DOING, which has high w...

Industry News

-

04-03

2025

Can plastic be turned back into oil?

Through pyrolysis, plastic waste can be converted into oil. Furthermore, the end product of plastic pyrolysis, pyrolysis...

-

03-25

2025

Where to dispose used engine oil in Malaysia?

In Malaysia, several options are available for used engine oil disposal, including authorized collection centers, recycl...

-

03-20

2025

Who are the manufacturers of automatic tyre pyrolysis plant?

DOING is one of the few manufacturers that can provide efficient, environmentally friendly and convenient automatic tire...

-

02-28

2025

What is the cost of pyrolysis furnace?

The cost of pyrolysis furnace is $15,000-$1,100,000. DOING will give your detailed price list of pyrolysis furnaces base...

-

01-09

2025

What's the process for the waste tyre pyrolysis oil to diesel conversion plant?

The waste tyre pyrolysis oil could be converted to diesel through heating, refining, cooling, collecting. This passage w...

-

12-03

2024

What are the components of a fully continuous pyrolysis system?

The machine components of a complete fully continuous waste tire pyrolysis system includes waste tire plastic shredding ...

- In Africa

- In Europe

- In America

- In Asia

Waste tire to diesel recycling plant was put into operation in South Africa

Nigeria waste tyre recycling to diesel project

Continuous process tyre pyrolysis plant will delivery to Tunisia

Nigeria waste tire recycling to fuel oil machine

Continuous waste tyre pyrolysis plant price

The continuous waste tyre pyrolysis plant price,the most important factor that in...

Profit analysis of fully automatic pyrolysis plant

Knowing the profits of the project will strengthen the determination to do the pr...

How to start continuous waste tyre pyrolysis plant in India?

6 things must be considered before starting continuous waste tyre pyrolysis plant...

What is the best waste oil disposal method?

What does waste tyre recycling plant refer to?

What are the steps of waste tire pyrolysis to oil?

What machines are used to recycle plastic into oil?

What's the difference between semi-continuous pyrolysis plant and fully continuous pyrolysis plant?

Can tires be turned into fuel? What machine can recycle waste tires into oil?

How many kinds of pyrolysis plants are there? How to choose a suitable one?

What can be used in pyrolysis plant to heat the pyrolysis reactor?

Is it necessary to buy a tire shredder for fully automatic continuous pyrolysis plant?

MAIN ADVANTAGES OF CONTINUOUS PYROLYSIS PLANT

Fully Pyrolysis High Oil Output

Accurate calculated pyrolysis system, ensure fully pyrolysis to get high oil output.

Unique sealing design

Unique sealing design of both feeding and slagging system for safety guarantee and environment protection.

Save Time and Energy

Continuous feeding, continuous slagging, save time and energy.

Fully Automatic With Low Labour Cost

Fully automatic with PLC control system, save manpower, reduce labour cost.

Unique slaggig system

Unique slaggig system for direct and convenient carbon black and steel wire separation.

Big Capacity

Single unit, small land occupy size, but with large capacity.

contact us

CONTACT USPhone:

+86-135-2669-2320WhatsApp:

8613526692320E-mail:

market@doingmachinery.comWechat: